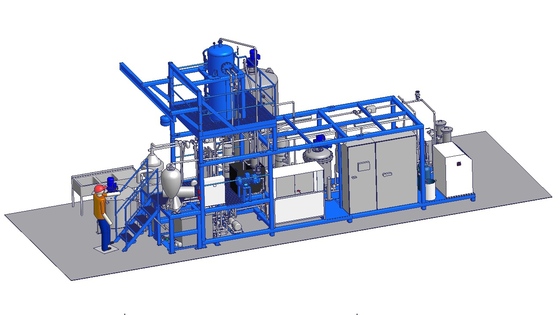

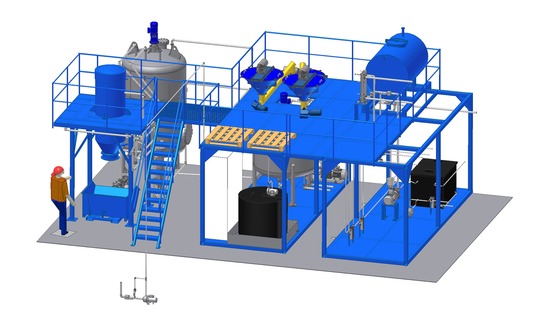

Vegetable Oil Refining

Vegetable oil obtained through pressing or extraction contains various unwanted impurities that naturally occur in the seeds. These substances include mainly phosphorus (bound to phospholipids), pigments, wax, and volatile particles. They may cause undesirable colouration, unwanted odour, and burning at contact surfaces, all of which hinders the use of crude oil in both food and technical industries. Farmet offers technological equipment for oil refining according to the customer’s needs. The process of oil refining has four steps: degumming, bleaching, dewaxing, and deacidification. We also offer separate technological solutions for each step.

The parameters of the entering oil significantly affect the quality of the process and material balance. As a general rule, lowering of the amount of impurities at the input leads to lower consumption of reaction agents, less by-product, and a higher-quality oil at the line output. Also, processing old oil is troublesome, since extended storage time causes oil to lose its potential for chemical reactions and refining.

Are you interested in increasing the value of your oil? Then you will appreciate our oil refining technology. This technology is tailored for every customer according to their demands on the resulting quality of oil. Do not hesitate to contact our experts, who will help you choose the best solution for you.