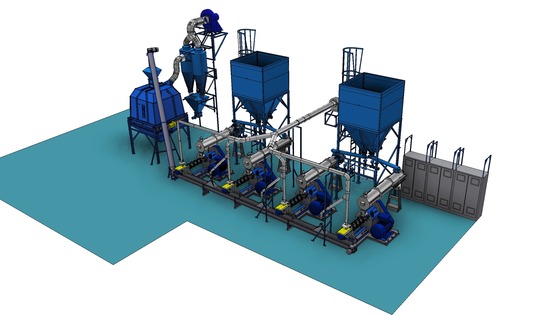

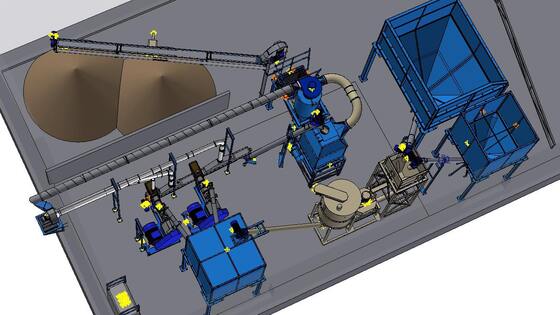

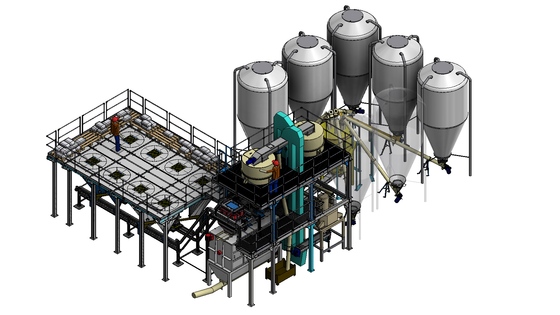

Feed Extrusion and Production of Feed Mixtures

The company Farmet offers highly effective and optimized technological solutions for highest-quality feed. All technological equipment is tailored for the customer and offers optimized operating costs while meeting strict sanitary regulations. Our production routine lays stress on reliability of machinery, so that problems and interruptions of operation are minimized.

Ease of use and maintenance and high work efficiency are the foremost assets of Farmet technology. Our solutions always come with technical support, engineering services, installation, commissioning, and a reliable and high-quality warranty and post-warranty service. Our goal is full customer satisfaction.