The product automatic filtration is designed for vegetable oil filtration, especially for the removal of solids, which are introduced during oilseed pressing. This technology is offered for middle- and large-scale press shops. The technology of automatic filtration stems from Farmet’s extensive experience with raw oil processing. Its main advantage is a highly sophisticated control system that allows optimization of the filtration process in accordance with the properties of raw oil. The technology is also always optimized to meet particular requirements of the customer.

The crude, solids-containing oil is accumulated in the mixing tank. Filtration is performed periodically in the pressure leaf filter. The filter itself consists of a cylindrical vertical pressure container with a conical bottom that ends with a drainage valve and a lid. The container is furnished with extensions for pipes and sensors (for pressure and levels). Operation of the filter meets specifications for pressure containers. Filtration plates are fixed on the inside of the filter. At the neck of the filter, there is a vibrator that serves to shake off the dried up filter cake out of the filtration plates.

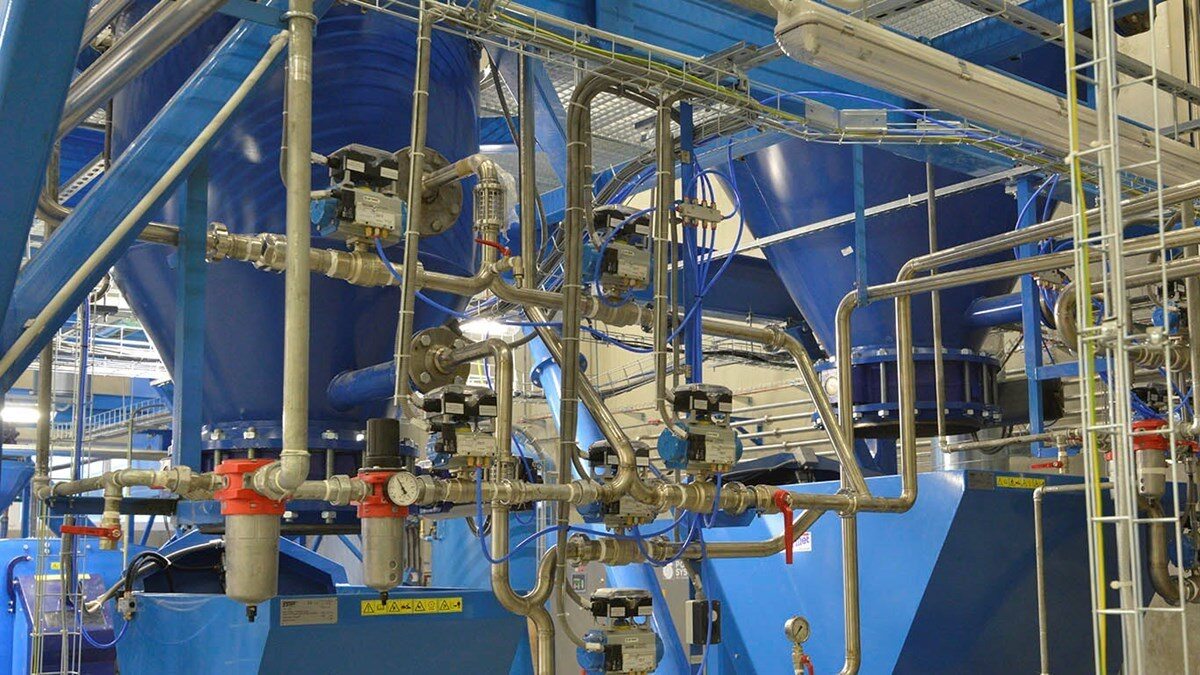

The filter is connected with the mixing tank through piping with built-in, pneumatically operated valves and pumps. Operation of the filter is controlled automatically by a PLC equipped with our control system FIC – Farmet Intelligent Control and its function “FILTER OPTIMAL”.

The company Farmet offers optional accessories that will satisfy even the most demanding customers. Nonetheless, the most convenient solutions are usually our turnkey deliveries, which are optimized from both the technical and economic perspectives, meet all your requirements and include the automatization of the entire process.

Filtration is offered at capacities between 9 and 500 tons of oil per day and is always optimized for a particular press shop.