Oil Processing

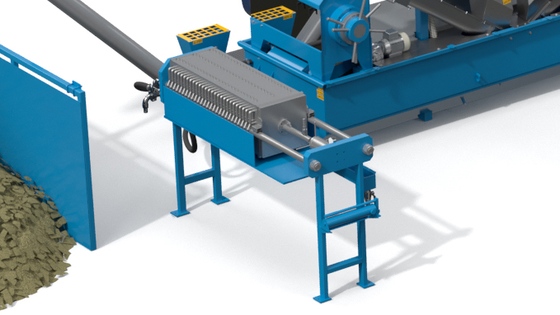

Vegetable oil obtained through pressing or extraction contains naturally occurring undesirable impurities that prevent direct use of the oil for food and technical purposes. These impurities can be categorized according to their solubility in oil.

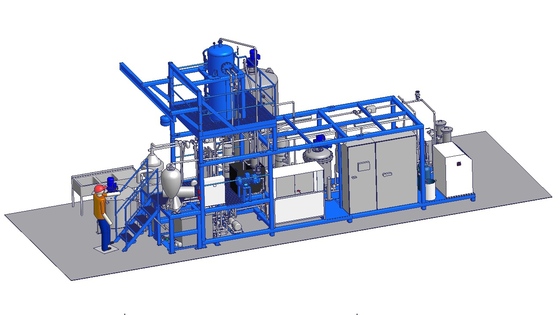

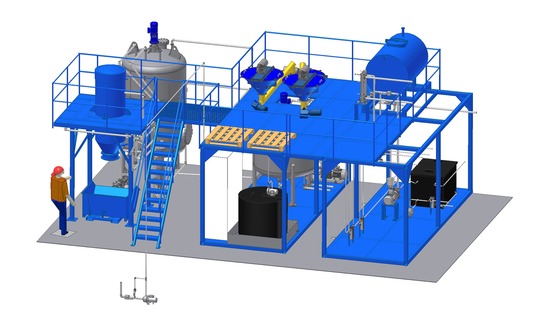

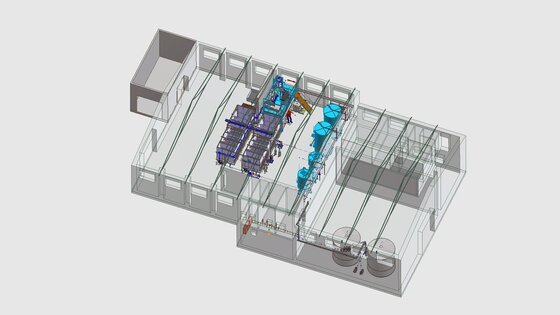

The particles insoluble in oil can be pieces of seeds that enter the oil during its processing. Oil-soluble substances include mainly phosphorus (bound to phospholipids), resin, pigments, wax, and volatile particles. These substances may cause undesirable colouration, unwanted odour at higher temperatures, and burning at contact surfaces, all of which hinders the use of the oil in food and technical industry. Farmet offers technological equipment for filtration and purification of the oil per customer’s wishes.

Do you seek to increase the value of your oil? You will then appreciate our technology for refining and filtration of oil. We alter this technology according to each customer’s demands and quality requirements. Do not hesitate to contact our experts, who will help you choose the best solution for you.