Farmet offers two versions of one-stage dehulling: one that lacks hull recovery and the other that includes hull recovery, which allows further dehulling of still-unhulled seeds.

Here is a list of advantages of dehulling prior to pressing (and achievable parameters):

1. Fibre content reduction leading to a higher-quality feed.

2. Increased oil yield.

3. Less wear of the pressing machinery.

4. Reducing wax and pigment content in oil.

Farmet offers two versions of one-stage dehulling: one that lacks hull recovery and the other that includes hull recovery, which allows further dehulling of still-unhulled seeds.

Here is a list of advantages of dehulling prior to pressing (and achievable parameters):

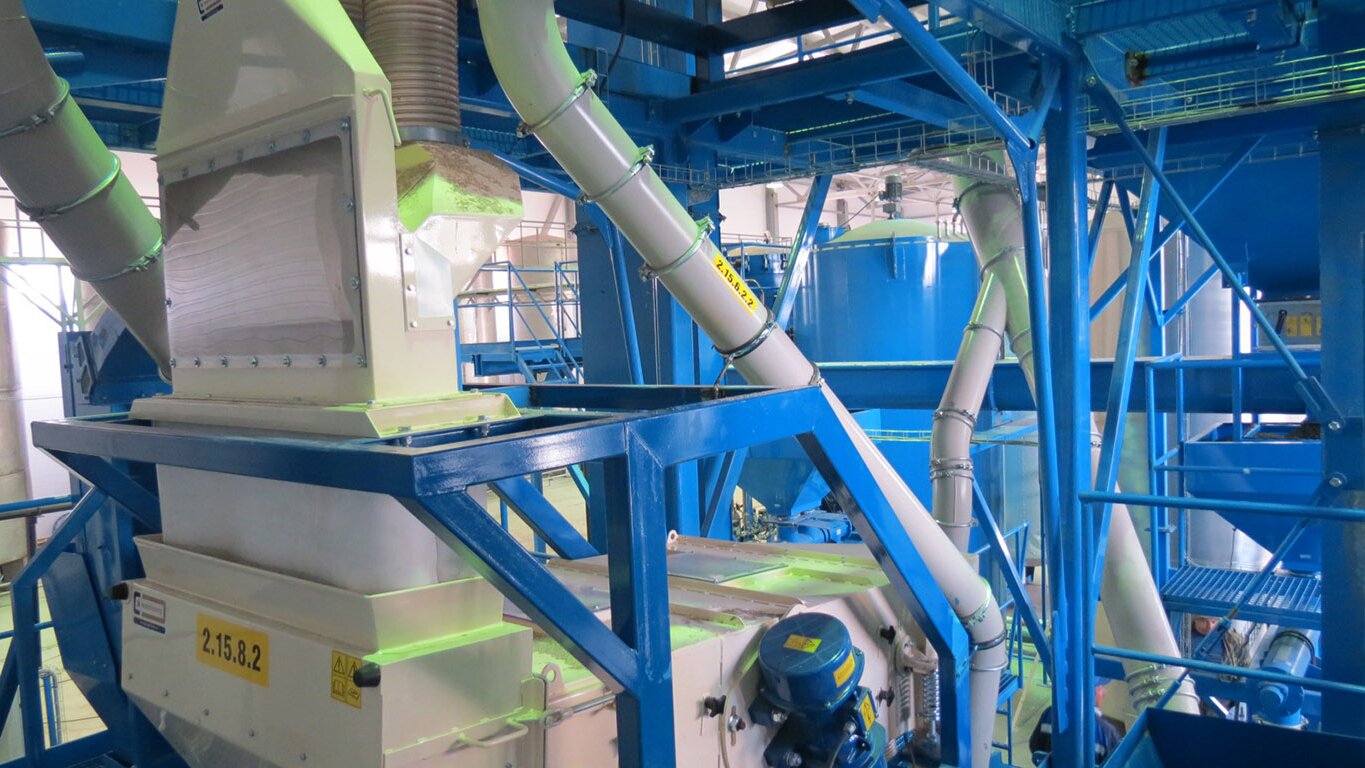

After dehulling, the seeds are sorted, at a first-stage sieve separator, into the following fractions:

This technology is relatively simple and therefore does not achieve optimal results (one-stage dehulling cannot be expected to reach fibre content in sunflower seed press cakes of less than 20 %, which is a common requirement).

The version of one-stage dehulling with hull recovery involves further dehulling of the largest fraction of unhulled seeds), which leads to their repeated disruption. One-stage separation, however, does not secure separating out of the greasy dust and kernel fragments, which are carried by the air flow and separated out along with the hulls.

The technology can be supplemented with the feature “HULL CHECK”, whereby the already separated hulls are sieved and aspirated again. Oily dust along with kernel remains are separated out, which lowers the loss of kernel material and therefore oil loss.

This procedure is intended for smaller-scale technologies, especially for one-level cold pressing, where oil content in the press cakes is hi

The company Farmet offers optional accessories that will satisfy even the most demanding customers. However, the most convenient solutions are usually our turnkey deliveries, which are optimized from both the technical and economic perspectives, meet all your requirements and include the automatization of the entire process.

The dehulling and hull separation technology is available at a spectrum of performance, using differently productive hullers and separators. Based on equipment productivity and practical experience of use, we have assembled tried and tested configurations of hullers and separators. These configurations are the most frequently implemented ones and they are well suited for the most common oilseed pressing technologies of the Farmet brand.