Feed Extrusion

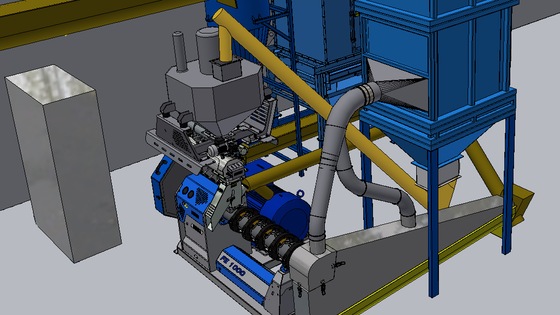

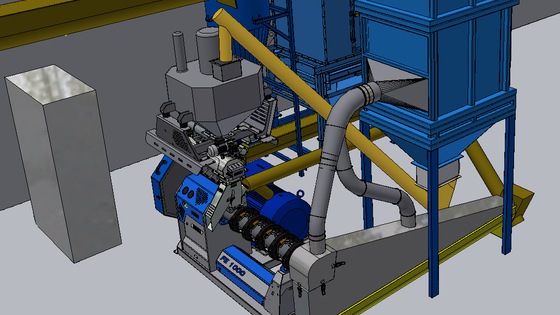

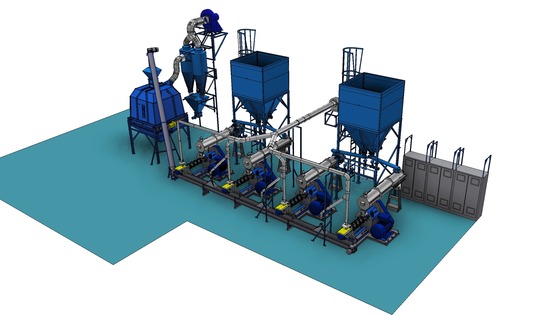

Farmet produces screw feed extruders that cover a range of performance and application. These feed extruders can be further assembled into extrusion lines. Overall performance is then determined by the number and type of equipment used. Performance, as well as extrudability of particular materials can be significantly influenced either by mechanical pre-treatment, such as grinding or crushing, or water addition, or steam injection.

The word EXTRUSION encompasses the processes of kneading, heating at high pressure, and squeezing the material through a die with the aim of reaching mechanical and heat treatment of the material. This method is also known as HTST (High Temperature Short Time), because of the short exposure to hot temperatures.

In feed industry, extrusion technology is used for two main purposes:

- Improving feed quality by mechanical and heat processing in the extruder

- Shaping of feed by squeezing the material through a die (into granules or pellets)

Implementing extrusion has the following advantages:

- Mechanical grinding. The feed attains fine structure that is convenient for digestion. During the expansion at the outlet of the extruder, inner structure of the material is disrupted, which increases its surface area and aids transport of nutrition in the digestive system.

- Transformation (denaturation) of proteins. Short-term exposure to the temperature of 100 °C with concurrent pressure inside the extruder cause effective transformation (denaturation) of proteins, which increases the energetic value of the feed.

- Deactivation of enzymes.

- Substantial reduction of anti-nutritional substances and natural toxins. Extrusion is effective at degrading many anti-nutritional substances. For example, the extrusion of soybeans leads to a significant reduction of urease activity. Another convenient advantage, for the nutrition of monogastric animals, is the reduction of trypsin inhibitors in the feed.

- Conditions inside the extruder (heat and pressure) kill bacteria, mould, and other unwanted organisms and pests. Extrusion thus stops production of mycotoxins, which leads to a longer storage life.

- Gelatinization of starch. Starch is both common and important feature of feed. During extrusion complex saccharides are degraded into more simple, which makes the feed easier to digest.

- Homogenization and shaping. During extrusion, all constituents of the feed are mixed. Squeezing through a matrix of particular profile can shape feed particles into different shapes (applicable, for instance, for pet food). Successful shaping and retention of the final form is only possible with extrudate that contains enough connective substances (most commonly starch).