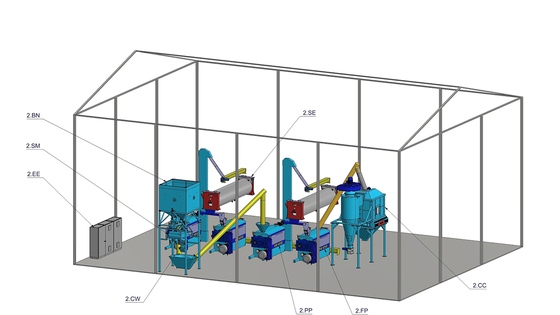

Cold-hot Pressing

Cold-hot pressing brings the benefits of cold pre-pressing with final hot pressing. The cold pressing step gives the highest-quality oil, ideal for cold cuisine. The press cake from the pre-press is then heated up to 100 °C and pressed again with a higher efficiency. This technology can be adjusted to separately handle the oil coming from the pre-press and the second press.