The technology of two-level cold pressing is convenient of oilseeds with oil content above 35 %. The most common examples are sunflower seed and rapeseed. The technology produces a high-quality, filtered oil as well as press cakes suitable for feed purposes.

The highest temperature reached in this process is 55°C, which meets the strictest requirements for cold pressing of oilseeds. The temperature of press cakes ranges between 60 and 80°C, the reduction of anti-nutritional substances is therefore only partial.

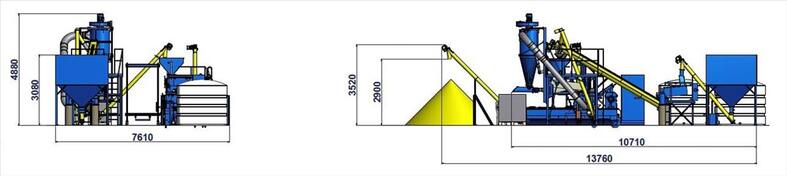

This is a technology of two-level cold pressing. The expeller press FS 350 is used as a pre-press. The press cakes from the pre-pressing are fed into the final press, which is also the model FS 350.

The expelled crude oil, still containing solid particles, flows into the settling tank, where sedimentation of the solids occurs. The sediment is then separated out by an integrated separator and returned back into the press for another round of pressing. The settling tank contains an integrated oil heating system, which, together with solids separation, guarantees a high efficiency of the filtration process.

The Compact pressing shop can be further expanded with the Dehulling and Shell Separation module, which allows the separation of kernels from shells, where part of the shells is removed and discharged as a by-product. This is especially suitable for processing sunflower and soybean seeds. Removing the shells increases the protein content in the pressed cakes, thus enhancing their feed value. The shells can be processed using the shell granulation accessory, which transforms the shells into pellets, thereby reducing the volume required for shell storage and enabling their energy utilization.

Another optional accessory is Continuous Seed Weighing at the technology input, and for increased cleaning requirements, we recommend including a Destoner to separate stones and heavier impurities.

For treating the pressed cakes, it is possible to purchase Moisturizing of the Cakes with water or additives and Granulation of the Cakes immediately after pressing. For hot pressing technologies, we also recommend Cooling of the Cakes using a counterflow cooler.

The filtered oil is pushed out by a filtration pump and must be directed into a tank. We recommend supplementing with an Oil Storage solution, using plastic tanks with capacities of 1 m³ or 7 m³. The oil storage can be equipped with a dispensing pump that enables transferring oil from the storage tanks into transport containers or tank trucks.

The modular press shop Compact CP2 is offered at performances between 300 and 600 kg per hour.