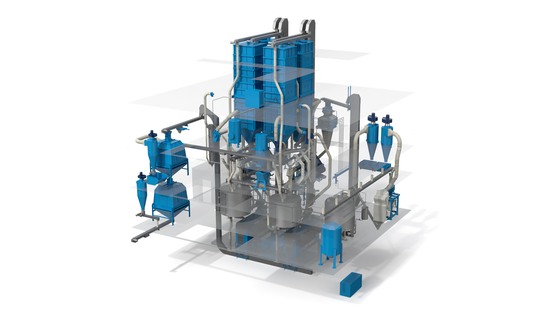

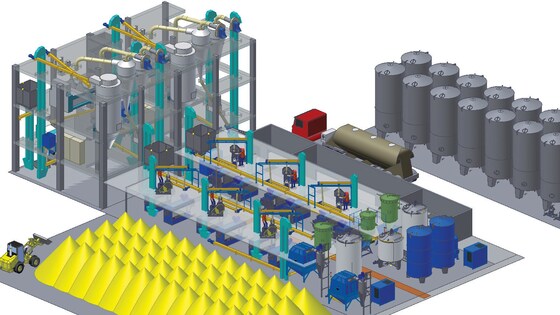

Pressing with Extrusion

A perfect combination of mechanical and thermal processing. It employs the benefits of extrusion for the subsequent pressing step (increasing oil yield).

Benefits of extrusion–pressing:

• Installed capacity ranges from small to very high scale.

• Technology free of chemical solvents, waste-free, environment-friendly, with lower energetic costs.

• Possibility of procesing organic-grown, GM-free, hexane-free, ecological products.

• Press cake of a high quality, heat-improved for high energy value, is ideal for the purposes of animal nutrition, especially for ruminant feed.

• Oil obtained is of high quality, lower in phospholipid content compared to solvent extraction.

• The EP1 technology uses a unique system of heat recuperation (lowering operation costs, increasing productivity and reduces return-on-investment).

A technology that is overall more efficient than solvent extraction.