Complex Oilseed Processing

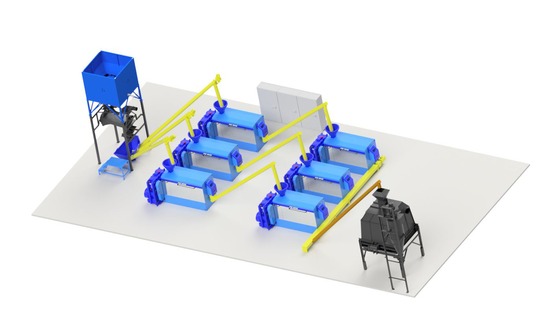

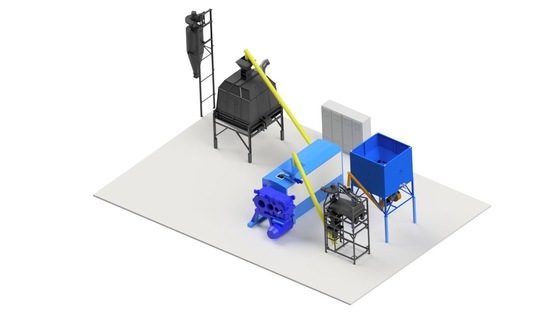

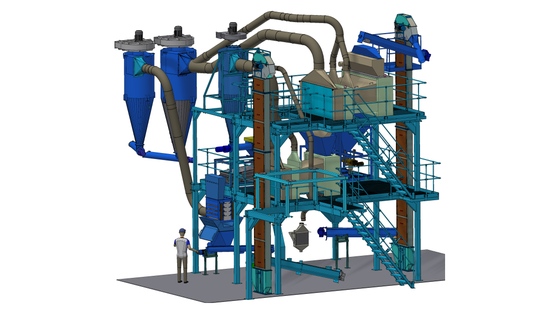

Thanks to the unique combination of our complete portfolio of oilseed screw presses and feed extruders, we highly recommend the exclusive technology of Pressing with Extrusion. This combination of both technologies will ensure the best results for the processing of oilseeds, especially for soybeans, rapeseed and sunflower.

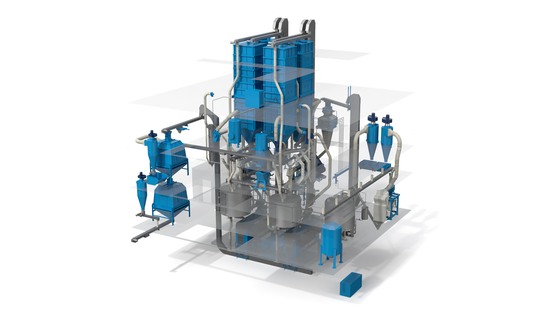

The technology of pressing plants developed in Farmet stands on more than two decades of experience in this field. This technology involves highly effective screw presses in various configurations, always adjusted and optimized for individual applications.

- The lowest operation costs owing to the Farmet technology, which uses an advanced system of energy recuperation.

- Hexane-free technology Farmet that is both cost-efficient and environment-friendly.

- Hexane-free technology Farmet brings you an ideal feed with an optimal ratio of fat (energy) and proteins.

- Hexane-free technology Farmet gives you the most effective feed at minimal costs.

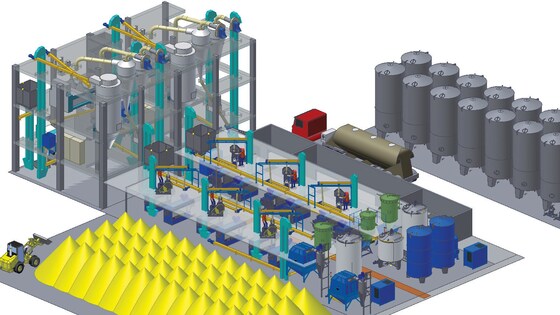

- Complex, integrated technological solutions guarantee minimal operation costs.

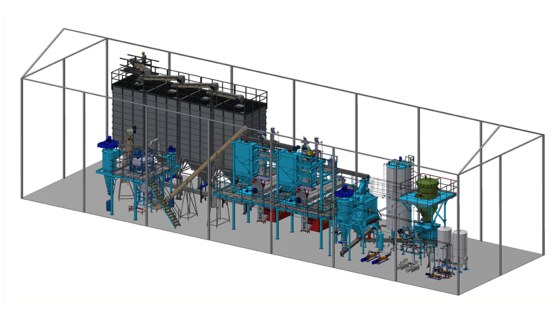

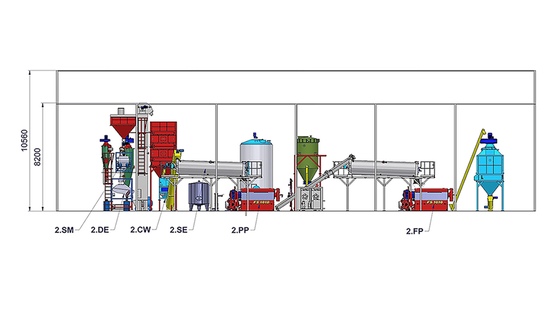

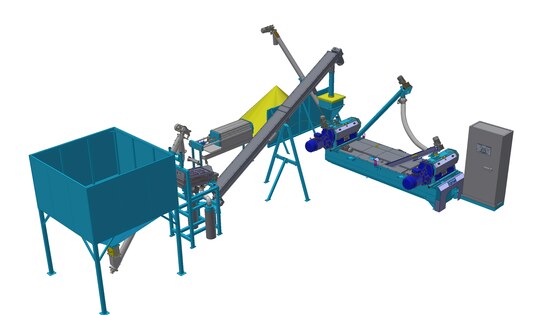

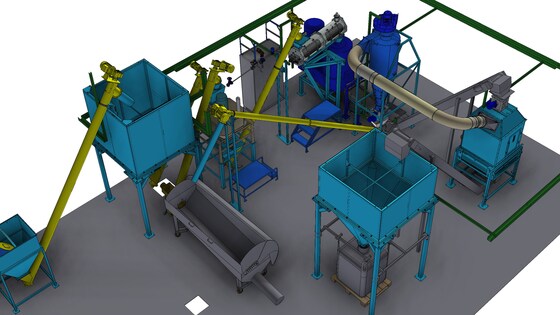

The different modifications and possible arrangements of the presses provide a broad range of solutions for concrete requirements on the pressing process: from very small capacities for the pressing of special oilseeds to large facilities processing 1000 tons daily. Due to the different properties of each oilseed variety, mainly oil content, the technology always needs to be precisely adjusted for the particular species, variety, or seed category.

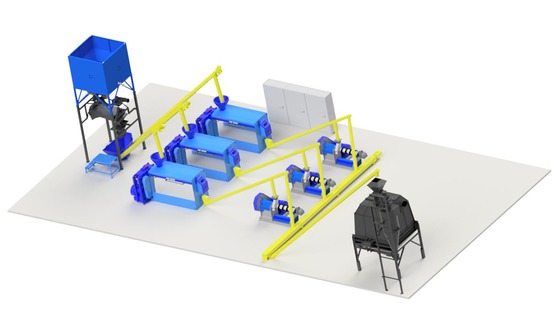

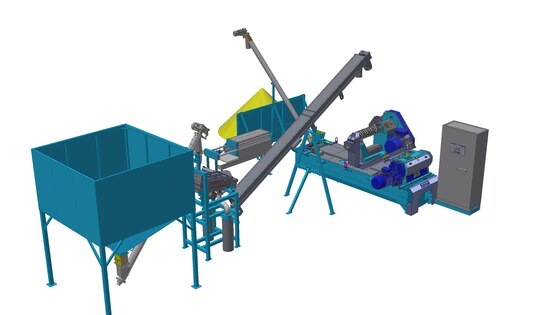

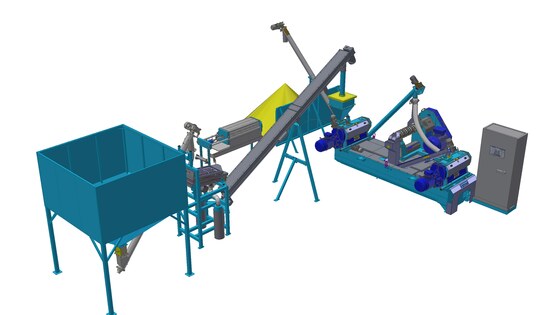

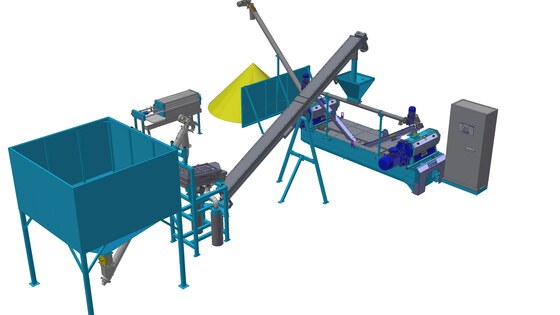

In our oilseed pressing technology, only endless screw presses are used; in diverse arrangements, employing diverse seed pre-treatment procedures.

In practice, the technology is usually categorized as follows:

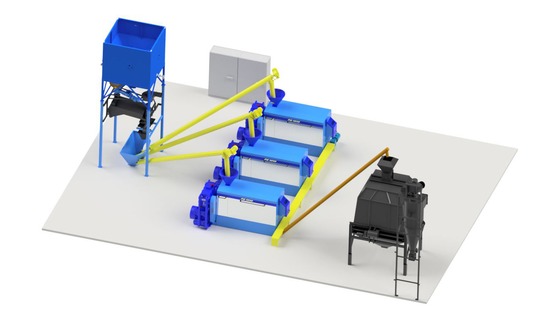

- One-stage or two-stage - this refers to the number of pressing steps which the seeds undergo. In two-stage pressing, the first press is referred to as ‘pre-press’ and the second as ‘final-press’. Two-stage pressing technologies are used to maximize yield especially in oilseeds high in oil content (above 30 % - e.g. rapeseed, sunflower seed). Soybean pressing (oil content ca. 20 %) usually employs one-stage pressing.

- Cold or hot pressing - indicates the temperature at which the pressing is done.

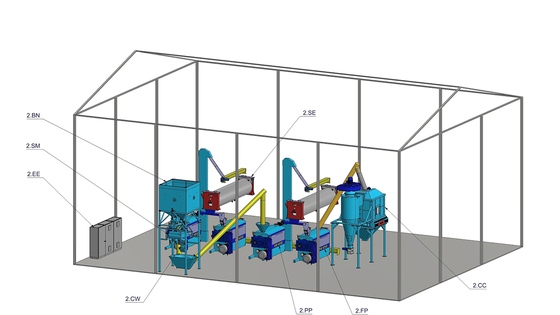

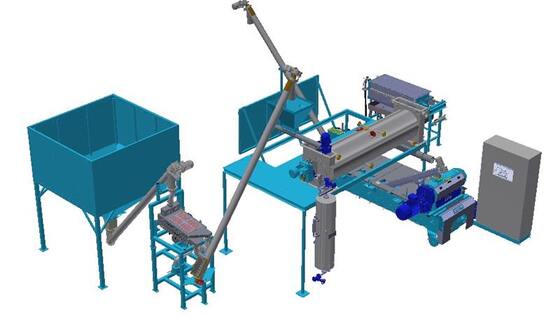

- Pressing with extrusion - the technology of feed extrusion brings substantial benefits to the pressing process. Combining both technologies will ensure the best results for a whole range of oilseeds, including soybean, rapeseed, and sunflower seed.

In cold pressing, the seeds are not heated up prior to pressing. The temperature of expelled oil does not 50 °C. This technology thus yields the highest-quality cold-pressed oil. However, the oil yield is overall lower, due to a significant amount of fat retained in the press cake (10 - 12 %). Heating up the seeds before pressing (e.g. in stack heaters) considerably increases the yield, at the cost of lower oil quality. Extrusion–pressing can lead to high oil yields. Also, extrusion leads to a thermal improvement of the press cake, in other words, to an increased digestibility and nutrient availability (reduction of anti-nutritional substances, denaturation of proteins, gelatinization of starches, creation of by-pass protein). The pressing with extrusion technology is therefore the best solution wherever there is emphasis on oil yield and quality press cake for feed or food purposes.

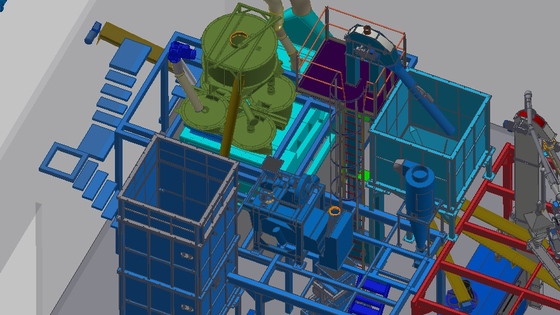

The advanced recuperation system developed by Farmet offers a considerable reduction in the operation costs of oilseed processing. The advantage lies mainly in the increase of the throughput of the line, at decreased energy costs. The result is thus both an economically and environmentally favorable solution, saving both your pocket and the planet.

A natural part of Farmet technologies is the system for intelligent control and visualization of the process, called Farmet Intelligent Control (FIC). The whole procedure of oilseed processing is controlled by an industrial computer (PLC) via a visualization PC from the control room, or alternatively by a touch screen placed near the device. The entire system is designed to reach optimal parameters and minimize unwanted disturbances and staff interventions into the technology.